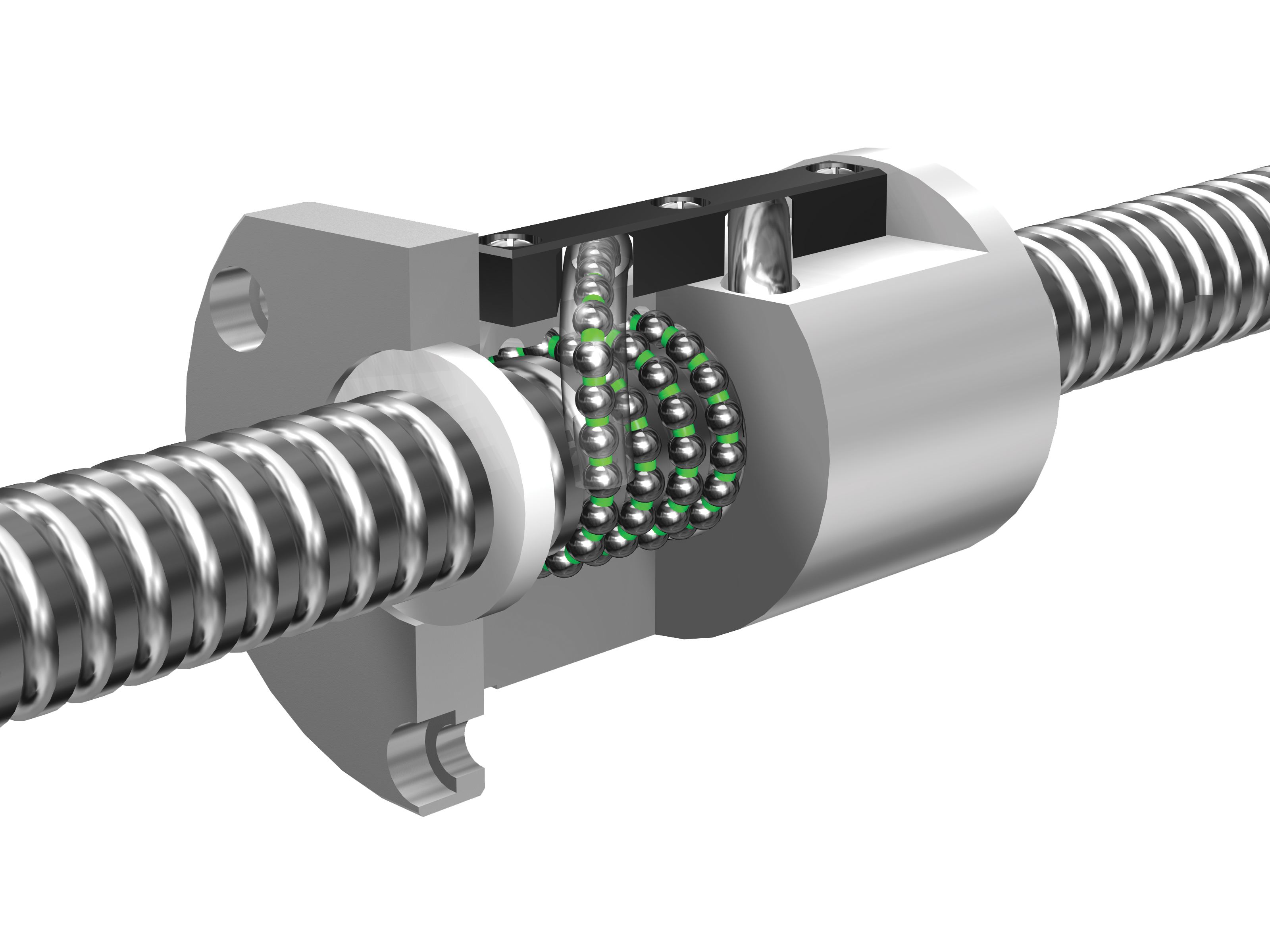

Servo or stepper motor connected to ball screw, which is used in automated machines It is a common structure, and the motion method is to change circular rolling into linear motion. General CNC pallets and some fine straight worktables are mostly driven by servo or stepper motors. But this simple drive, the organization is very simple, the main components are: motor, screw, screw lock nut bearing seat, bearing and so on. However, the general screw is reciprocating work, requiring very high precision, and some repeatability is as high as 0.001mm.

High-precision organization also needs a reasonable structural design, I will share it here part of my experience.

A vertical high-speed reciprocating action of drilling spindle carriage, cumulative motion method. The required depth accuracy is 0.005mm.

Parts selection: P4 grade 2504 ball screw, 7003C/DB angular touch bearing, elastic Couplings, stepper motors.

The key here is an expensive part------7003C/DB corner Touch the bearing. The bearing size is 17*35*20 (single is 10), paired device, the price is 800 yuan per pair.

Back-to-back angular touch bearings can accept forces from two axial directions, and can accept both High-speed rotation and a certain radial force, so it is a very common kind of bearing on the ball screw. The installation method of the angular touch bearing is very particular, and the force and rigidity received are also different in different installation directions. Therefore, special attention should be paid to the design selection and installation.

;

7003C/DB angular touch bearing can be adjusted , the accuracy can reach 0.001mm. The accuracy level is greater than the P4 level.

Back-to-back installation method, the other end of the screw is suspended, if you want to install a bearing at the other end , then the bearing of 7003CT should be installed, and the CT tail number indicates that it is installed in series. Tandem bearings can only accept forces in one direction.

The machine I mentioned above is a drilling machine. Descending vertically, drilling stainless steel, the depth of machining accuracy is required to be 0.01, while the actual accuracy of this machine is 0.005. The screw stroke is 100mm, and the speed of the stepping motor is about 400 rpm.

For fine machines, the accuracy of Guaranteed the same. Generally speaking, the machine with screw feeding guarantees the accuracy:

1. Silk bar

2. Rails

3. Installation method

4. Other mechanical aspects

5. Control program.

All of the above are indispensable.

13695780858